Stamping parts are the basic components for almost all of industrial

sections. Stamping parts fabrication processes including material blanking,

stamping and surface treatment. Almost all the metal material including steel,

copper, aluminum etc. can be stamped. The surface treatment of stamping parts would

be in accordance with the client’s requirements.

Auwell has more

than 20 years in stamping parts development and production, it is one of our

most important product lines. Auwell’s rich experience, cost effective, fast

turnaround and big production capacity as well as the favorable payment term

has won high reputation from our clients.

Auwell tilbyder stemplingsdele i produktionsmåde 2: konventionel stempling og progressiv stempling. Til lille mængde og / eller stor størrelse bruger vi traditionel stemplingproces trin for trin, til stor mængde og mindre størrelse giver progressiv stempling store fordele med hensyn til produktivitet og omkostningsbesparelse.

The stamping parts material can be low

carbon steel, mild steel, stainless steel, copper,

brass, aluminum, and alloy steel. Auwell’s production capacity is 800 ton

stamping machine, material thickness can be from 0.2mm to 12mm.

Surfacetbehandlingen til stempling af dele kan være:

-Polering

-Zinc-plating

-Fornikling

-Chrome plating

-Silver plating

-KTL

-Hot dip galvanization

-Painting

-Powder coating

-Anodizing

Competitive Advantages

-Rig oplevelse

Mere end 20 års erfaring med stempling af deleudvikling og -produktion, især til de europæiske og nordamerikanske markeder, med solid forståelse af de materielle, tekniske og kvalitetsstandarder over hele verden.

-Fast Turnaround

Generally, we provide a quotation within 3 working days. Combining the

latest manufacturing technologies and facilities, Auwell can provide fast

prototypes for stamping parts in just 2 weeks for simple projects.

-Omfattende løsningsudbyder

Auwell leverer omfattende tjenester til stempling af dele, der starter fra design, gennem prototyping, værktøj / fixturudvikling, prøveudtagning, masseproduktion og til logistisk og post-salg support.

-Stive QC-politikker

The most rigorous quality policy starts from material control, and is

followed through to final pre-shipment inspection. Material certificates

include the mill certificate, 3rd party chemical components, and mechanical

property reports, as well as RoHS and REACH reports upon request. Other reports

include dimensional reports, surface treatment thickness, and salt fog test

reports, etc. We structure our processes, creating Flow Charts and Control Plans

before production, making sure all QC processes are in accordance with

ISO9001-2015 requirements and drawing specifications.

-Fleksibel betalingsperiode

Tooling payments need to be pre-paid. For mass production, we offer

flexible payment terms, reasonable credit terms will be given, the client only

pays when they are happy with the product they received. For long-term

projects, we offer call-off inventory services for fast delivery requirements.

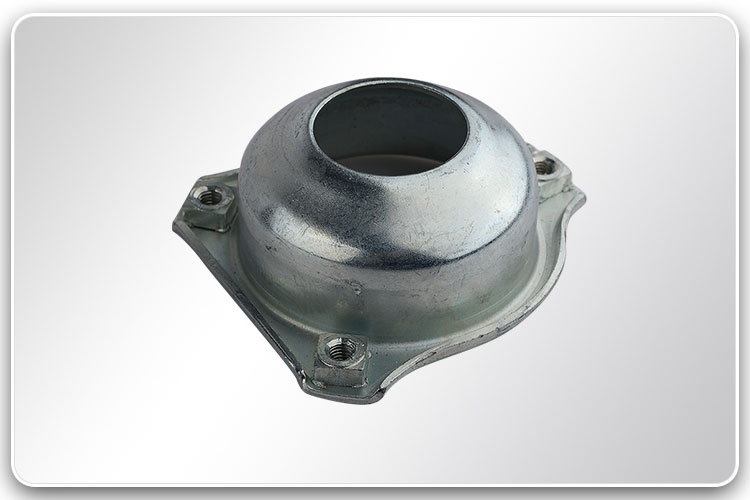

Stemplingsdelene, der vises i dette afsnit, er nogle af de produkter, Auwellhas har udviklet til vores kunder, alle stemplingsdelene er fremstillet af OEM, følgende produkter er kun til demonstrationsformål. Hvis klienterne har stemplingsdele, der skal udvikles, er det varmt velkommen til at kontakte os for detaljer.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик