Beskrivelse

Klemringe fra Auwells produktlinje er den mekanisme, der forbinder / kanaler2 rør sammen lineært ved at fastspænde de forfladede rørkanter.

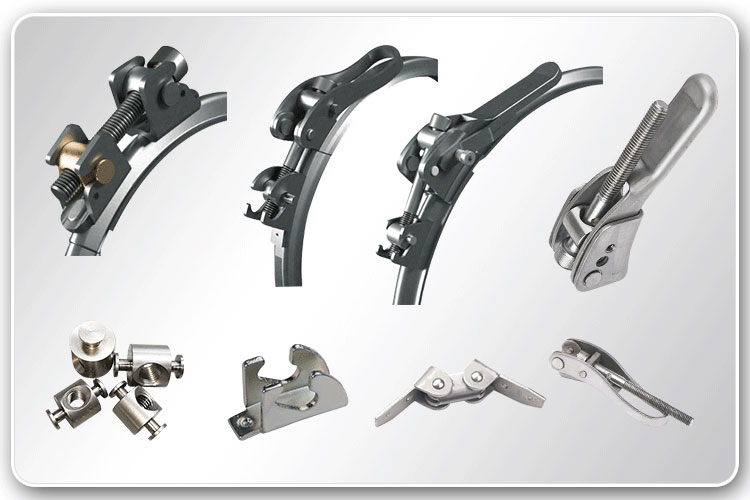

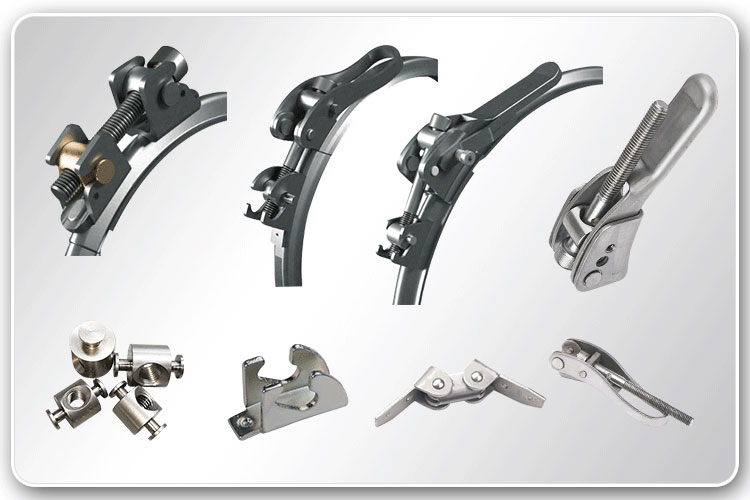

Klemringen er dannet af en flad stålstang til den ønskede form og diameter. Den består af 2 halvringe, den lukkede side er forbundet med en skruebolte eller hængsel, åbningssiden har også 2 monteringsveje - skruemekanismen eller hurtigudløsningsmekanismen (hurtigstik). For begge monteringsmetoder kan ringen strammes og justeres til den ønskede tæthed.

In general, the diameter of clamping rings range from 80mm to 630mm, the profile of the rings can be U shaped, V shaped, or custom made upon clients’ request. The thickness of the rings range from 1mm to 3mm. If the pipeline is for liquid transportation, rim seals will be used, the seal material can be NBR or silicone, with a maximum pressure of up to 4.5bar.

Before Clamping

Before Clamping

Efter fastspænding

Efter fastspænding

The half clamping ring parts are assembled with a saddle (stamping parts), hinges, and fast connectors by butt welding followed by hand welding for reinforcement. Before assembling the 2 halves, for carbon steel or stainless steel parts, zinc plating and shot blasting may be applied respectively upon request.

Auwell has more than 15 years of experience in manufacturing and supplying components for clamping ring products including fast connectors, hinges, saddles (stamping parts), and turning parts, at this moment, 100% of products exported to Germany for our distinguished clients. By using optimized technology and programming, our products have been proven as excellent in quality at an affordable price. Auwell is proud of its high productivity for producing these products in a cost-effective way.

The Spannring Parts displayed are custom made exclusively for our distinguished clients. We are happy to offer competitive price to all inquiries from potential clients.

Technical Specifications

-Material: ST12, ST37, Q235B, Stainless steel 304, 316L or upon request

-Sadeltykkelse: 2,5 mm

-Turning parts: Diameter: Φ12mm with M6 thread orΦ14mm with M6 thread or upon request

-Drejedele lavet af specialfremstillet CNC drejebænk, fuldautomatisk produktion,sadlen er lavet af progressiv dyse for kvalitet

consistency and higher productivity.

Fordele

-Rich Experience

More than 15 years of experience in clamping rings components development and production, especially to the European markets. With solid understanding of the material, technical and quality standards worldwide.

-Fast Turnaround

Generelt leverer vi et tilbud inden for 3 arbejdsdage. Ved at kombinere de nyeste produktionsteknologier og -faciliteter kan Auwell levere hurtige prototyper på bare 3 uger til enkle projekter inklusive hurtige stik.

-Comprehensive Solution Provider

Auwell leverer omfattende tjenester til fastspænding af ringkomponentprojekter, der starter fra design, gennem prototyping, værktøjs- / armaturudvikling, prøveudtagning, masseproduktion og til logistisk og post-salg support.

-Stive QC-politikker

The most rigorous quality policy starts from material control, and is followed through to final pre-shipment inspection. Material certificates include the mill certificate, 3rd party chemical components, and mechanical property reports, as well as RoHS and REACH reports upon request. Other reports include dimensional reports, surface treatment thickness, and salt fog test reports, etc. We structure our processes, creating Flow Charts and Control Plans before production, making sure all QC processes are in accordance with ISO9001-2015 requirements and drawing specifications.

-Flexible Payment Term

Tooling payments need to be pre-paid. For mass production, we offer flexible payment terms, reasonable credit terms will be given, the client only pays when they are happy with the product they received. For long-term projects, we offer call-off inventory services for fast delivery requirements.

Applications

Spænderinge er meget brugt i næsten alle industrisektorer, herunder:

-Automotive

-Landbrugsmaskiner

-Food machinery

-Farmaceutisk industri

-Olieindustrien

-Construction

-Transportation

Følgende kataloger over klemmeringe-komponenter er dem, som Auwell har produceret og leveret til vores fremtrædende kunder. Klik på de relevante billeder for detaljer. Vær opmærksom på, at de fleste produkter kun er til demonstrationsformål.

Fast Connector for Clamping Rings

Fast Connector for Clamping Rings

Saddle for Clamping Rings

Saddle for Clamping Rings

Turning Parts for Clamping Rings

Turning Parts for Clamping Rings

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик