Description

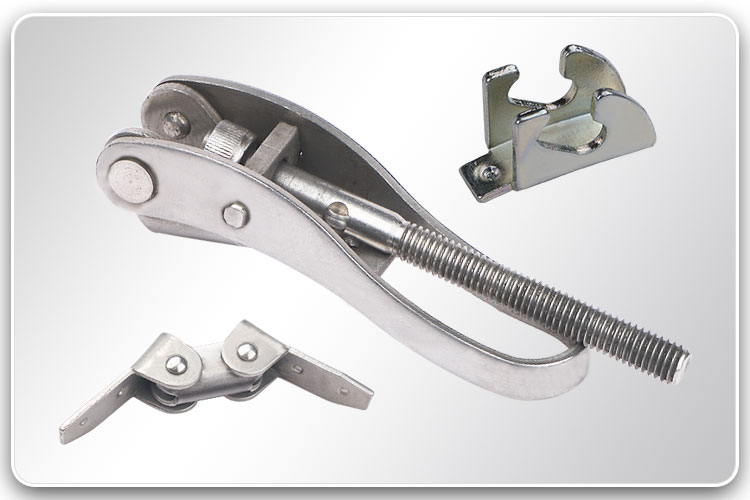

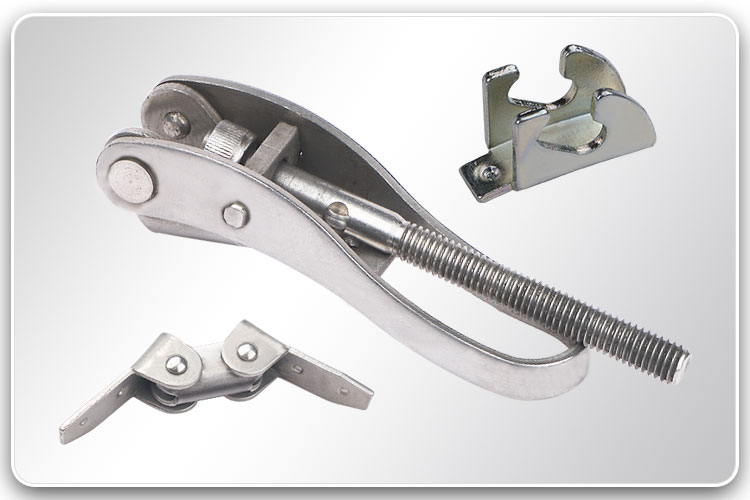

Sadlen til fastspændingsringe (stemplingsdel) er den kritiske komponent til fastspændingsringprodukter. Hver klemring består af mindst 4 sadeldele. Sadlen til fastspændingsringe er direkte samlet med fastspændingsdelene gennem stødsvejsning efterfulgt af håndsvejsning til forstærkning.

The essential control points for the Saddle for Clamping Rings are the

tolerance for the slots and the height of the butting welding bulges. The slot

contact point with the turning parts arm need to be pressed in, making sure that

the turning parts can rotate freely while being held in place. The definite and

consistent height of the welds is the guarantee for high welding quality.

Auwell has more than 15 years of experience in manufacturing and supplying

Saddle for Clamping Rings product, at this moment, 100% of products exported to

Germany for our distinguished clients. Equipped with a progressive die machine,

Auwell can produce Saddle for Clamping Rings parts efficiently for

cost-effective reasons. Progressive stamping is the guarantee of quality

consistency.

Ved hjælp af optimeret teknologi og programmering har vores sadel til fastspændingsprodukter vist sig at være fremragende i kvalitet til en overkommelig pris. Auwell er stolt af sin høje produktivitet til at producere disse produkter på en mest effektiv måde.

Følgende video viser vores professionelle måde i sadlen til fastspændingsproduktion:

The Saddle for Clamping Rings products displayed are custom made

exclusively for our distinguished clients. We are happy to offer competitive price

to all inquiries from potential clients.

Tekniske specifikationer

-Materiale: ST12, ST37, Q235B, rustfrit stål 304, 316L eller efter anmodning

-Saddle thickness: 2.5mm

-Surface: light oil rust

protection

-Pakkeoplysninger: Kan fås efter anmodning

Advantages

-Rich Experience

Mere end 15 års erfaring med sadel til fastspænding af ringeprodukter, udvikling og produktion, især til de europæiske markeder. Med solid forståelse af materialet, tekniske og kvalitetsstandarder over hele verden.

-Hurtig vending

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell can provide fast prototypes for saddle for

clamping rings in just 3 weeks for saddle parts.

-Comprehensive Solution Provider

Auwell leverer omfattende tjenester til sadel til fastspænding af ringe-projekter, der starter fra design, gennem prototyping, værktøjs- / armaturudvikling, prøveudtagning, masseproduktion og til logistisk og post-salg support.

-Stive QC-politikker

The most rigorous quality

policy starts from material control, and is followed through to final

pre-shipment inspection. Material certificates include the mill certificate,

3rd party chemical components, and mechanical property reports, as well as RoHS

and REACH reports upon request. We structure our processes, creating Flow Charts

and Control Plans before production, making sure all QC processes are in accordance

with ISO9001-2015 requirements and drawing specifications.

-Fleksibel betalingsperiode

Værktøjsbetalinger skal forudbetales. Til masseproduktion tilbyder vi fleksible betalingsbetingelser, der gives rimelige kreditbetingelser, kunden betaler kun, når de er tilfredse med det produkt, de har modtaget. For langsigtede projekter tilbyder vi afbrydelsestjenestetjenester for hurtige leveringskrav.

Related Products

Hurtig forbindelse til fastspændingsringe

Hurtig forbindelse til fastspændingsringe

Drejedele til fastspændingsringe

Drejedele til fastspændingsringe

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик