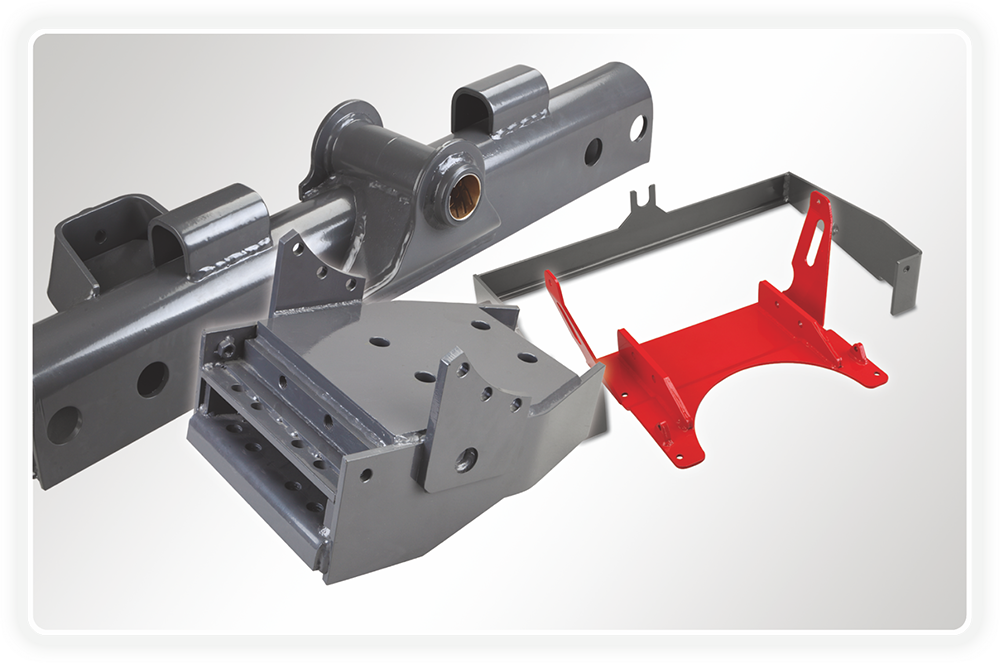

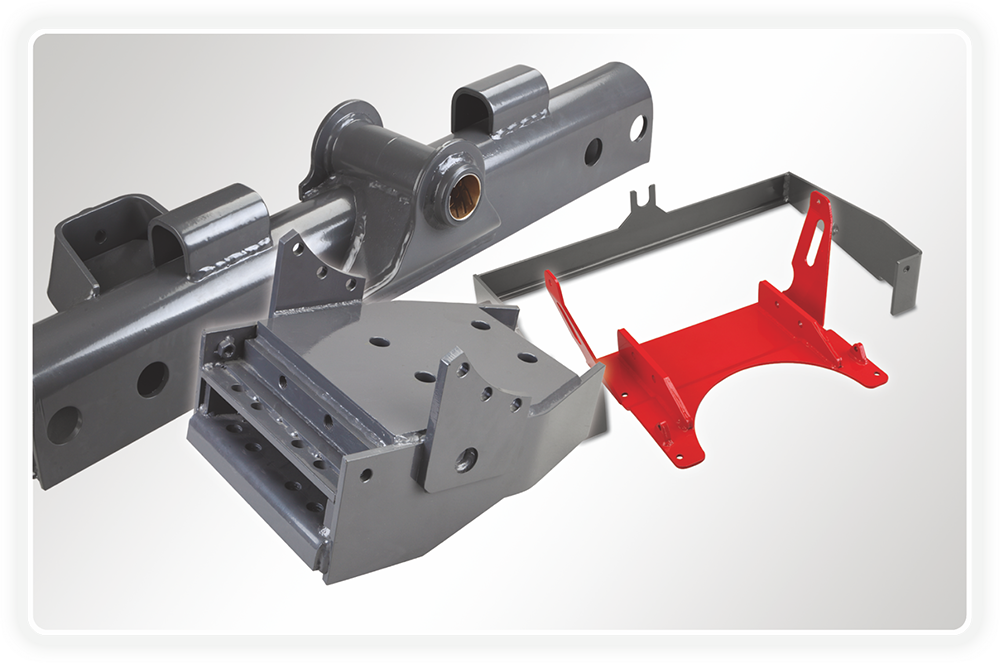

Auwell startede udvikling af metalplader landbrugsmaskiner OEM-dele i år 2011, hovedsagelig til AGCO MASSEY-FERGUSON BX200-serien. Det dækker forskellige sektorer fra enkle stemplingsdele til tunge og komplekse monteringsgrupper.

Agriculture Machinery industry has its own unique requirements, it is critical to use right material and manufacturing process in accordance with the drawing requirements. Auwell organizes the production of Agriculture Machinery OEM Parts from TS16949 registered and experienced manufacture to ensure the product quality.

The process of Agriculture Machinery OEM Parts manufacturing includes 4 steps - cutting, forming, assembling, and surface treatment.

-Cutting Process

Vi tilbyder forskellige skæreindstillinger med en tykkelse fra 1 mm til 150 mm, dette inkluderer iltskæring, laserskæring, plasmaskæring. For små dele er stempling den mest almindelige måde til materialeblankering.

-Dannelsesproces

The forming process typically includes bending, hydraulic press forming with die, punching, and milling. The nature of the parts’ design determines the method used. Deburring is an essential procedure before welding and assembling.

-Samling

For OEM-dele til landbrugsmaskiner er den vigtigste proces til samling svejsning. Armaturer skal prædesignes og fremstilles for at sikre et produkt uden forvrængning efter svejsning. Nogle områder kræver fræsning efter samling. Et sæt testmålere er præudviklet til kvalitetsinspektion, hvilket sikrer produktets komplette funktionalitet.

-Overfladebehandling

The normal surface treatment processes of Agriculture Machinery OEM Parts include electrophoresis (KTL), powder coating, painting, and zinc plating. For all surface treatment, we offer coating adhesion, thickness, and salt fog tests or, other tests to be conducted upon request. Anodizing is available for aluminum materials.

Tekniske specifikationer

-Material

Blødt stål, rustfrit stål, kobber, messing, aluminium og legeret stål.

-Machine capacity

1,200 ton hydraulic press machine, 800 ton stamping machine, material cutting thickness up to 150mm for oxygen cutting, 60mm for plasma cutting, and 25mm for laser cutting. Maximum part size: 2,000*1,500mm.

-Other specifications

Auwell is capable in designing and developing necessary tools for Agriculture Machinery OEM Parts including forming dies, fixtures for welding, and test gauges for mass production QC. CMM is available for sample dimensional inspection. Surface treatment includes KTL, powder coating, painting and zinc plating. Flow Chat and Control Plan will be submitted to the client for discussion before production. PPAP documents are submitted together with the initial samples.

Fordele

-Rich Experience

More than 9 years of experience in Agriculture Machinery OEM Parts development and production, especially to the European and North American markets, with solid understanding of the material, technical and quality standards worldwide.

-Hurtig vending

Generelt leverer vi et tilbud inden for 3 arbejdsdage. Ved at kombinere de nyeste produktionsteknologier og -faciliteter kan Auwell levere hurtige prototyper på bare 3 uger til enkle projekter.

-Omfattende løsningsudbyder

Auwell leverer omfattende tjenester til landbrugsmaskiner OEM-dele fra design til prototyping, værktøjs- / inventarudvikling, prøveudtagning, masseproduktion og til logistisk support og salg efter salg.

-Rigid QC Policies

The most rigorous quality policy starts from material control, and is followed through to final pre-shipment inspection to griculture Machinery OEM Parts orders. Material certificates include the mill certificate, 3rd party chemical components, and mechanical property reports, as well as RoHS and REACH reports upon request. Other reports include dimensional inspection, surface treatment thickness, and salt fog test reports, etc. We structure our processes, creating Flow Charts and Control Plans before production, making sure all QC processes are in accordance with TS16949 requirements and drawing specifications.

-Fleksibel betalingsperiode

Tooling payments need to be pre-paid. For mass production, we offer flexible payment terms, reasonable credit terms will be given, client only pays when they are happy with the product they received. For long-term projects, we offer call-off inventory services for fast delivery requirements.

The following catalogues of Agriculture Machinery OEM Parts are the ones which Auwell has produced and supplied to our distinguished worldwide clients. Please click the relevant pictures for details. Please be advised, most of the products are for demonstration purpose only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик