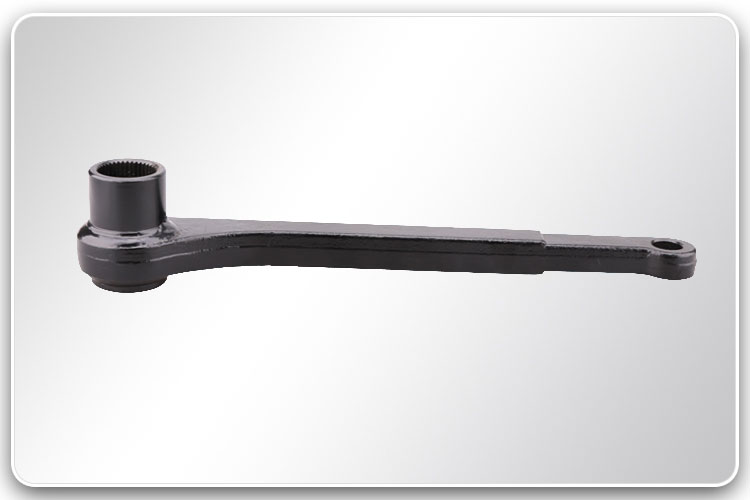

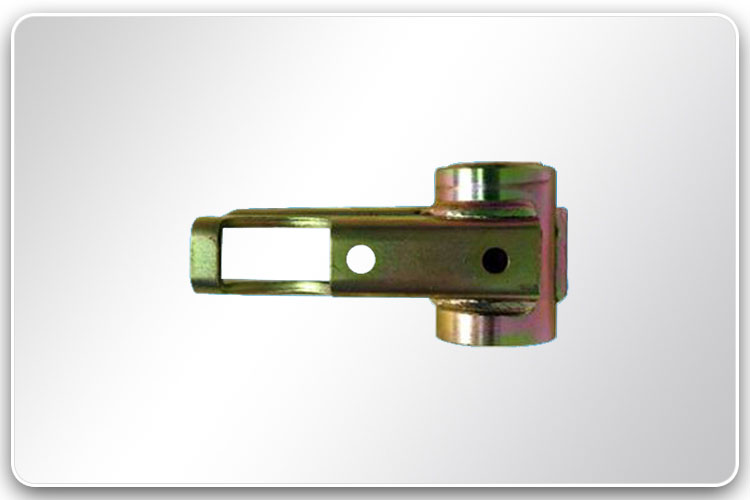

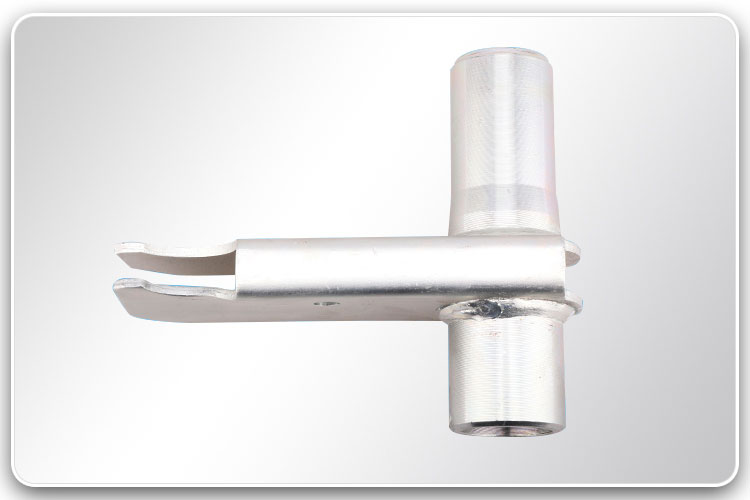

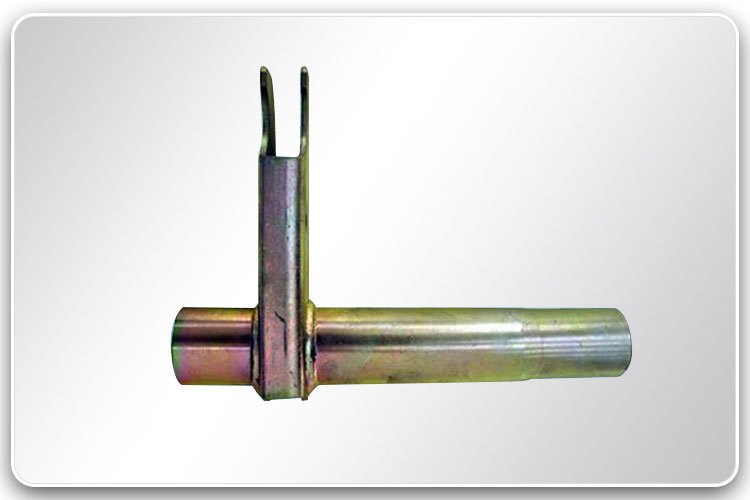

Automotive Adjustable Torsion Bar is one of Auwell’s OEM product line. So far, we have developed more than 10 different Automotive Adjustable Torsion Bar products for our worldwide clients.

Automotive Justerbar Torsion Bar består af en stang og spline samlet ved svejsning, stangen kan laves ved plasmaskæring, smedning og stempling afhænger af produktets art og anvendelse. Stangen svejses med spline efterfulgt af overfladebehandling, KTL og zinkbelægning er den mest almindelige overfladebehandlingsproces.

Udover serien Automotive Adjustable Torsion Bar tilbyder vi også følgende relaterede produkter til bilindustrien:

-Knuckle-serien

-Stikserie

-Gasket Pad Series

-Kabinet

-Wheel Hub series

Kunder, der er interesserede i Automotive Adjustable Torsion Bar-serien eller lignende produkter, bedes du kontakte os for detaljer.

Technical Specifications

-Materiale

Mildt stål, legeret stål.

-Surface Treatment

KTL, zinc plating, powder coating, painting

-Other specifications

I stand til at designe og udvikle nødvendige værktøjer til Automotive Justerbar Torsion Bar, herunder formstøbning, armaturer til svejsning og testmålere til masseproduktion QC. CMM er tilgængelig for prøvdimensionel inspektion. Overfladebehandling inkluderer KTL, pulverlakering, maling og zinkbelægning. Flowchat og kontrolplan vil blive sendt til klienten til diskussion inden produktion. PPAP-dokumenter indsendes sammen med de indledende prøver.

Advantages

-Rig oplevelse

More than 10 years of experience in Automotive Adjustable Torsion Bar development and production, especially to the European and North American markets, with solid understanding of the material, technical and quality standards worldwide.

-Hurtig vending

Generelt leverer vi et tilbud inden for 3 arbejdsdage. Ved at kombinere de nyeste produktionsteknologier og -faciliteter kan Auwell levere hurtige prototyper på bare 3 uger til enkle projekter.

-Comprehensive Solution Provider

Auwell leverer omfattende tjenester til Automotive Adjustable Torsion Bar startende fra design gennem prototyping, værktøjs- / armaturudvikling, prøveudtagning, masseproduktion og til logistisk og post-salg support.

-Rigid QC Policies

The most rigorous quality policy starts from material control, and is followed through to final pre-shipment inspection. Materiale certificates include the mill certificate, 3rd party chemical components, and mechanical property reports, as well as RoHS and REACH reports upon request. Other reports include dimensional inspection, surface treatment thickness, and salt fog test reports, etc. We structure our processes, creating Flow Charts and Control Plans before production, making sure all QC processes are in accordance with TS16949 requirements and drawing specifications.

-Fleksibel betalingsperiode

Værktøjsbetalinger skal forudbetales. Til masseproduktion tilbyder vi fleksible betalingsbetingelser, rimelige kreditvilkår gives, kunden betaler kun, når de er tilfredse med det produkt, de har modtaget. Til langsigtede projekter tilbyder vi afbrydelsestjeneste til hurtige leveringskrav.

The following catalogues of Automotive Adjustable Torsion Bar are the ones which Auwell has produced and supplied to our distinguished worldwide clients. Please click the relevant pictures for details. Please be advised, most of the products are for demonstration purpose only.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик