Auwell har rig erfaring med at levere Sheetmetal Automotive OEM Parts til verdensomspændende kunder, der dækker næsten alle sektorer fra små stemplingsdele til store karosseri- og chassiskomponenter.

Bilindustrien har sin egen materialestandard, det er vigtigt at bruge det rigtige materiale i overensstemmelse med tegningskravene. Auwell organiserer produktionen af Sheetmetal Automotive OEM Parts fra TS16949 registreret fremstilling for at sikre produktkvaliteten.

Processen med fremstilling af Sheetmetal Automotive OEM-dele inkluderer 4 trin - skæring, formning, samling og overfladebehandling.

-Cutting Process

We offer various cutting options with thickness ranged from 1mm to 150mm, this includes oxygen cutting, laser cutting, plasma cutting. For small parts, the stamping is the most common way for material blanking.

-Forming Process

Formningsprocessen inkluderer typisk bøjning, hydraulisk presseformning med matrice, stansning og fræsning. Arten af delens design bestemmer den anvendte metode. Afgratning er en vigtig procedure inden svejsning og samling.

-Assembling

For Sheetmetal Automotive OEM Parts er hovedprocessen ved samling svejsning. Armaturer skal prædesignes og fremstilles for at sikre et produkt uden forvrængning efter svejsning. Nogle områder kræver fræsning efter samling. Et sæt testmålere er præudviklet til kvalitetsinspektion, hvilket sikrer produktets komplette funktionalitet.

-Surface Treatment

The normal surface treatment process for Sheetmetal Automotive OEM Parts include electrophoresis (KTL), powder coating, painting, and zinc plating. For all surface treatment, we offer coating adhesion, thickness, and salt fog tests or, other tests to be conducted upon request. Anodizing is available with aluminum materials.

Tekniske specifikationer

-Materiale

Blødt stål, rustfrit stål, kobber, messing, aluminium og legeret stål

-Machine capacity

1,200 ton hydraulic press machine, 800 ton stamping machine, material cutting thickness up to 150mm for oxygen cutting, 60mm for plasma cutting, and 25mm for laser cutting. Maximum part size: 2,000*1,500mm.

-Andre specifikationer

Capable in designing and developing necessary tools for Sheetmetal Automotive OEM Parts including forming dies, fixtures for welding, and test gauges for mass production QC. CMM is available for sample dimensional inspection. Surface treatment includes KTL, powder coating, painting and zinc plating. Flow Chat and Control Plan will be submitted to the client for discussion before production. PPAP documents are submitted together with the initial samples.

Fordele

-Rich Experience

More than 20 years of experience in Sheetmetal Automotive OEM Parts development and production, especially to the European and North American markets, with solid understanding of the material, technical and quality standards worldwide.

-Hurtig vending

Generally, we provide a quotation within 3 working days. Combining the latest manufacturing technologies and facilities, Auwell can provide fast prototypes in just 3 weeks for simple projects.

-Comprehensive Solution Provider

Auwell leverer omfattende tjenester til Sheetmetal Automotive OEM-dele, der starter fra design, gennem prototyping, værktøjs- / armaturudvikling, prøveudtagning, masseproduktion og til logistisk support og salg efter salg.

-Stive QC-politikker

The most rigorous quality policy starts from material control, and is followed through to final pre-shipment inspection to Sheetmetal Automotive OEM Parts orders. Materiale certificates include the mill certificate, 3rd party chemical components, and mechanical property reports, as well as RoHS and REACH reports upon request. Other reports include dimensional reports, surface treatment thickness, and salt fog test reports, etc. We structure our processes, creating Flow Charts and Control Plans before production, making sure all QC processes are in accordance with TS16949 requirements and drawing specifications.

-Flexible Payment Term

Tooling payments need to be pre-paid. For mass production, we offer flexible payment terms, reasonable credit terms will be given, client only pays when they are happy with the product they received. For long-term projects, we offer call-off inventory services for fast delivery requirements.

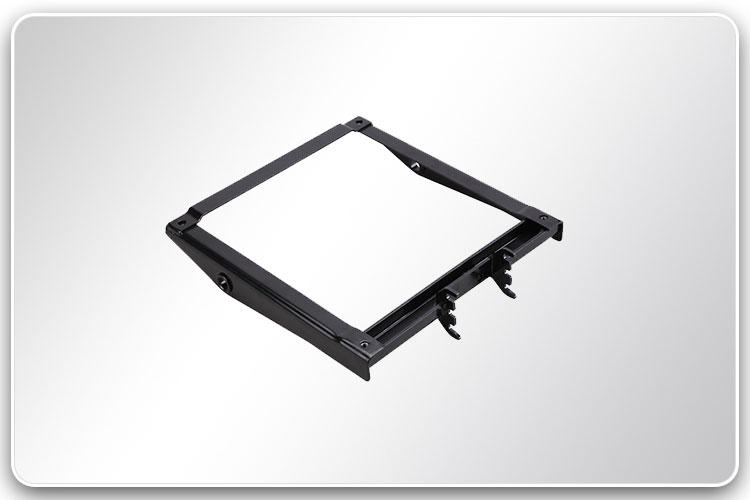

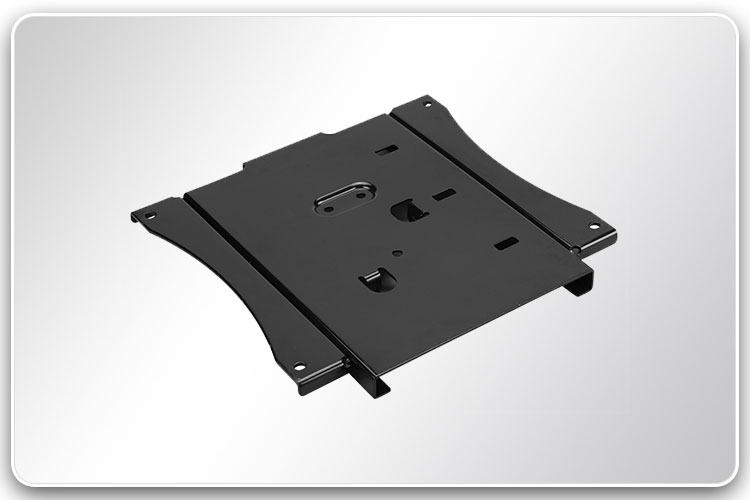

Følgende kataloger over Sheetmetal Automotive OEM-dele er dem, som Auwell har produceret og leveret til vores fremtrædende verdensomspændende kunder. Klik på de relevante billeder for detaljer. Vær opmærksom på, at de fleste produkter kun er til demonstrationsformål.

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик