Beskrivelse

Die-casting er en metalstøbningsproces, der er kendetegnet ved at tvinge smeltet metal under højt tryk ind i et formhulrum. Formhulrummet oprettes ved hjælp af to hærdede værktøjsstål-matricer og fungerer på samme måde som en sprøjtestøbning under processen. Det typiske materiale til højtryksstøbningsarealluminium, zink, magnesium, kobber og tinbaserede legeringer. Afhængigt af typen af metal, der støbes, anvendes en varm eller koldkammermaskine. Auwell leverer typisk tjenester til varmekammeraluminium og zinkstøbeforme og produkter.

Støbning af højtryksstøbning kan udføres i et enkelt eller flere hulrum, brug af enhedsmatricer eller en kombination af matricer afhænger af produktkravene.

Different type of dies in the die casting process:

-Enkelt hulrum til fremstilling af en komponent

-Flere hulrum til at producere flere identiske dele

-Unit die to produce different parts at one time

-Combination die to produce several different parts for an assembly

The casting equipment and the metal dies represent large capital costs. It

is thus especially suited for a large quantity of small to medium sized

castings, which is why high pressure die casting produces more castings than

any other casting process. High pressure die casting is characterized by an excellent

surface finish (by casting standards) and dimensional accuracy.

High pressure die casting is now considered as an industrial procedure,

used to manufacture parts for sale, or as part of machines for any other

commercial or industrial production. The process allows production of accurate

products to the desired size, shape, and thickness with tight tolerances,

making it the most simple yet effective casting process, essential for creating

metal parts with specified details and quality demands.

Højtryksstøbning er bevist at være gavnlig for produkterne. I denne proces kan der foretages forskellige ændringer i produktionen. Producenter bruger mindre midler og mindre tid på at fremstille de producerede trykstøbte dele, som er mere attraktive for købernes øjne.

High pressure die casting can eliminate post-machining and repeated

molding. The process is very economical and finished products made under this

process are accurate and long-lasting.

High pressure die casting is an efficient, economical process offering a

broader range of shapes and components than any other manufacturing technique.

Parts have a long service life and may be designed to complement the visual

appeal of the surrounding part.

Fordele of high-pressure die casting are as following:

-Højhastighedsproduktion

High-pressure die casting

supports complex shapes within closer tolerances compared to many other mass

production processes. Little or no machining is required and thousands of

identical castings can be produced before additional tooling is required.

-Fremragende dimensionel nøjagtighed og stabilitet

Højtryksstøbning producerer dele, der er holdbare med dimensionel konsistens og samtidig opretholder tætte tolerancer. De er også varmebestandige.

-Strength and weight

High-pressure die casting

parts have considerable high tensile strength at 415mpa. Thin wall castings are

stronger and lighter than those possible with other casting

methods.

-Multiple finishing techniques

Højtryks-støbegods kan fremstilles med glatte eller strukturerede overflader, og de er letbelagte eller færdigbehandlet med minimal overfladeforberedelse.

-Forenklet samling

High pressure die casting

provides integral fastening elements, such as bosses and studs. Holes can be

cored and made to size using tap drills, external threads can otherwise be

cast.

Auwell offers various types of services to fulfill the clients’

requirements. We have a rich experience in designing and manufacturing high

pressure die casting tools for the worldwide market, especially EU countries. We

produce dies and cast products, including machining and surface treatment, for

our clients.

Tekniske specifikationer

-Core Element Material

H13, 1.2344 (X40

CRMoV51), 1.2367(X38CrMoV5-1), H11, 1.2343 (X38CrMoV5-1)

Bolstermateriale: P20,1.2312, 1,2738

-Standardkomponenter

HASCO, LKM standard or custom

made

-Populært produktmateriale

AL226, AL230, AlSi10Mg,

360,380,383, 413 and A304 K-alloy, ADC12, ADC10, Zamak 3, Zamak 5, ZA-8, ZA-12

and ZA-27 etc.

-Product surface finishing

Inkluderer men er ikke begrænset til: pensel, liniepolering, polering med høj grovhed, spejlpolering, sandblæsere, anodisering, zinkbelægning, forkromning, fornikling, pulverlakering, sølvbelægning, E-coat, våd maling, silkescreening og stenciling etc.

-Maksimal bearbejdning af ClosingForce

4,000 tons, part weight:

5-30,000g

Fordele

-Rig oplevelse

Mere end 20 års erfaring inden for udvikling og produktion af trykstøbningsprodukter til højtryk, især til de europæiske og nordamerikanske markeder med solid forståelse af materielle, tekniske og kvalitetsstandarder over hele verden.

-Fast Turnaround

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell can provide initial samples in just 5 weeks

for simple projects.

-Omfattende løsningsudbyder

Auwell leverer omfattende tjenester til højtryksstøbningsprojekter, der starter fra design, gennem prototyping, værktøjs- / armaturudvikling, prøveudtagning, masseproduktion og til logistisk og post-salg support.

-Rigid QC Policies

Den strengeste kvalitetspolitik starter fra materialekontrol og følges op til den afsluttende inspektion før forsendelse. Materielle certifikater inkluderer møllecertifikatet, kemiske komponenter fra tredjeparter og rapporter om mekaniske egenskaber samt RoHSand REACH-rapporter efter anmodning. Andre rapporter inkluderer dimensionelle rapporter, overfladebehandlingstykkelse og salttåge testrapporter osv. Vi strukturerer vores processer, skaber flowdiagrammer og kontrolplaner inden produktion, idet alle QC-processer er i overensstemmelse med ISO9001-2015 krav og tegningsspecifikationer.

-Flexible Payment Term

For mass production, we

offer flexible payment terms, reasonable credit terms will be given, the client

only pays when they are happy with the product they received. For long-term

projects, we offer call-off inventory services for fast delivery requirements.

Ansøgninger

High pressure die casting products have widely been used in almost all

industrial sectors including:

-Aerospace and defense

-Automotive

-Agriculture Machinery

-Energy

-Elektronik

-Construction

-Transport

-Industrial

-Forbrugerprodukter

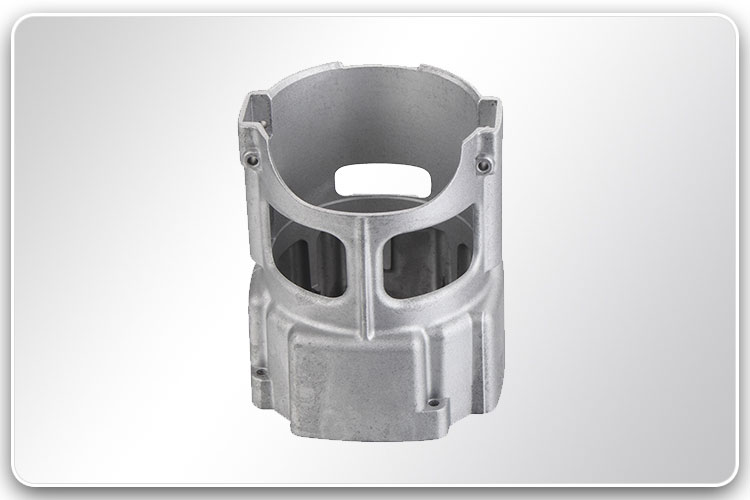

Følgende kataloger over højtryksstøbeprodukter er dem, som Auwell har produceret og leveret til vores fremtrædende verdensomspændende kunder. Klik på de relevante billeder for detaljer. Vær opmærksom på, at de fleste af produkterne kun er til demonstration.

Aluminium Die Casting Automotive Parts

Aluminium Die Casting Automotive Parts

Aluminium trykstøbning industrielle dele

Aluminium trykstøbning industrielle dele

High Pressure Die Casting Tooling

High Pressure Die Casting Tooling

Højtrykszink trykstøbningsdele

Højtrykszink trykstøbningsdele

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик