Duplex stainless steels

are a family of stainless steels. They are designed to provide better corrosion

resistance, particularly chloride stress corrosion and chloride pitting

corrosion, and higher strength than standard austenitic stainless steels such

as Type 304 or 316. The main differences in composition, when compared with an

austenitic stainless steel is that the duplex steels have a higher chromium

content, 20–28%; higher molybdenum, up to 5%; lower nickel, up to 9% and

0.05–0.50% nitrogen. Both the low nickel content and the high strength

(enabling thinner sections to be used) give significant cost benefits. They are

therefore used extensively in the offshore oil and gas industry for pipework

systems, manifolds, risers, etc and in the petrochemical industry in the form

of pipelines and pressure vessels. In addition to the improved corrosion

resistance compared with the 300 series stainless steels duplex steels also

have higher strength.

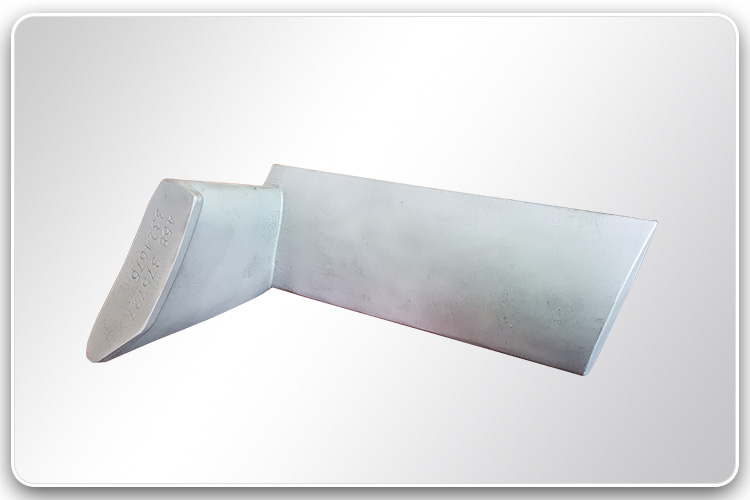

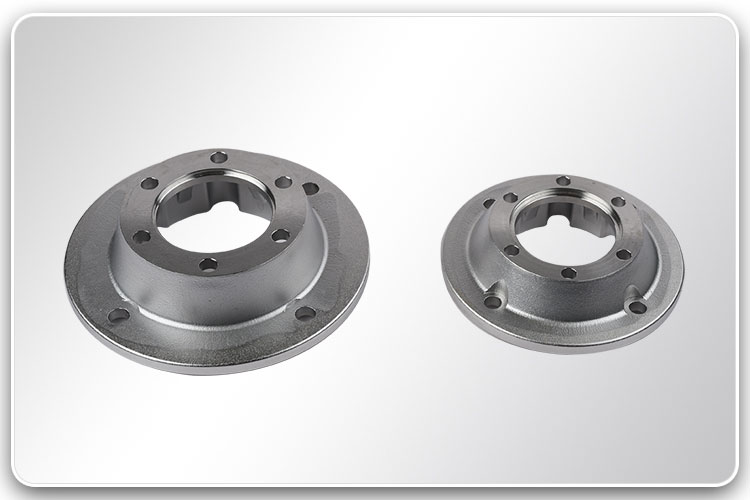

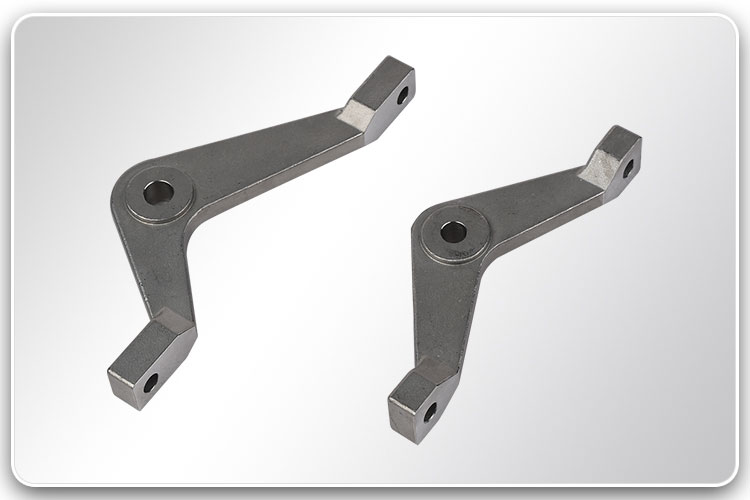

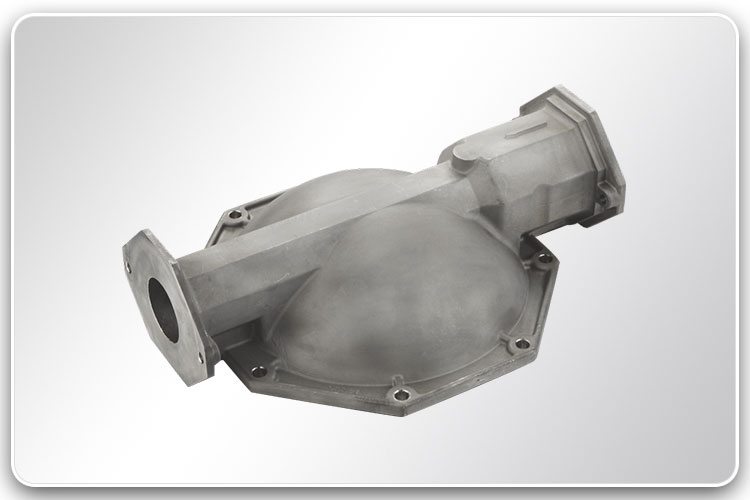

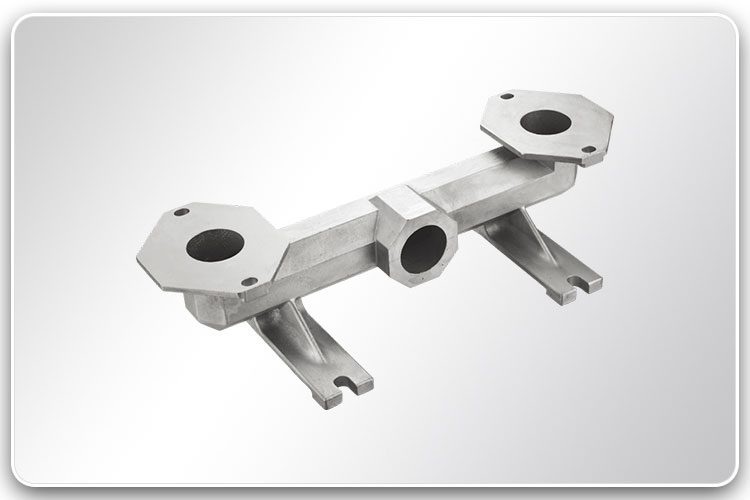

EN 1.4462 duplex stainless

steel casting is one of the stainless steel casting product lien we developed

for our clients, it also called 2205, X2CrNiMoN22-5-3 is its steel designation.

This is the typical Standard duplex (PREN range: 28–38) that has been widely

used.

|

Designation

|

Standard

|

Kemiske sammensætninger (%)

|

|

C

|

Si

|

Mn

|

P

|

S

|

Cr

|

Mo

|

Ni

|

N

|

Cu

|

|

1.4462

|

EN 10088-1 2014

|

Maks.

|

0.03

|

1.00

|

2.00

|

0.035

|

0.015

|

23.00

|

3.50

|

6.50

|

0.20

|

-

|

|

Min.

|

|

|

|

|

|

21.00

|

2.50

|

4.50

|

0.05

|

|

|

Designation

|

Standard

|

Physical Property

|

|

0.2 Proof (MPA)

|

Træk (MPA)

|

Forlængelse (%)

|

|

1.4462

|

EN 10088-1 2014

|

Maks.

|

|

880

|

|

|

Min.

|

450

|

650

|

25

|

Auwell starts development

of 1.4462 duplex stainless steel casting products 15 years ago for a German

client for swimming pool facility. After casting, we also made machining in

accordance with the drawing for the client for this 1.4462 duplex stainless steel

casting product.

Vi leverer følgende rapporter til klienten efter anmodning om 1.4462 duplex-støbning i rustfrit stål:

-Chemical components

-Testrapport om fysisk ejendom

-Hårdhedsrapport

-Ruhedsrapport

-Metallographic analysis

report

-Radiographic test report

-Varmebehandlingsrapport

-Dimensional report

-3D-scanningsrapport

Auwells konkurrencemæssige fordele:

-Rich Experience

More than 3 years of

experience in 1.4462 duplex stainless steel casting products development and production, especially to the European markets, with

solid understanding of the material, technical and quality standards.

-Hurtig vending

Generally, we provide a

quotation within 3 working days. Combining the latest manufacturing

technologies and facilities, Auwell can provide fast prototypes in just 3 weeks

for simple projects.

-Omfattende løsningsudbyder

Auwell provides

comprehensive services for 1.4462 duplex stainless steel casting product starting from designing, through prototyping, tooling/fixture

development, sampling, mass production, and to logistic and post-sale support.

-Rigid QC Policies

Den strengeste kvalitetspolitik starter fra materialekontrol og følges op til den afsluttende inspektion før forsendelse til 1.4462 duplex-støbningsordrer i rustfrit stål. Materielle certifikater inkluderer møllecertifikat, kemiske komponenter fra tredjeparter og rapporter om mekaniske egenskaber samt anmodning om rapporter om RoHS og REACH. Andre rapporter inkluderer dimensionelle rapporter, overfladebehandlingstykkelse og salttåge testrapporter osv. Vi strukturerer vores processer, skaber flowdiagrammer og kontrolplaner inden produktion, og sørger for, at alle QC-processer er i overensstemmelse med ISO9001-2015 krav og tegningsspecifikationer.

-Fleksibel betalingsperiode

Tooling payments need to

be pre-paid for 1.4462 duplex stainless steel casting product development. For mass production, we offer flexible payment terms, reasonable credit

terms will be given, client only pays when they are happy with the product they

received. For long-term projects, we offer call-off inventory services for fast

delivery requirements.

Hot Tags: 1,4462 Duplex rustfrit stålstøbning, producenter, leverandører, fabrik, tilpasset, fremstillet i Kina, Kina

English

English  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Azərbaycan

Azərbaycan  Slovenský jazyk

Slovenský jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик